E119 Boiler Error Code: Low Pressure Fault Causes and Fixes

The E119 boiler error code indicates low system water pressure. This fault is mostly present in Baxi and Potterton boiler models. Your boiler can’t function safely until the pressure is restored.

This e119 boiler error appears when the water pressure in the central heating system drops below a certain recommended level. Low water pressure can make your heating system inefficient, and your boiler might also shut down as a safety precaution.

If there are ongoing pressure issues with your boiler, having a boiler cover can help you minimise the cost of unexpected boiler failures. Let’s explore more details about the e119 boiler fault code and how to resolve this issue and get your boiler working again.

What Does E119 Mean on a Boiler

The boiler error E119 means that your boiler’s system pressure has dropped too low. This typically means below 0.5 bar. Many modern boilers are designed to shut down automatically when they detect a significant drop in pressure. Running the boiler at low pressure can cause damage to its internal components.

How to Fix E119 Error on a Boiler

The E119 boiler error code is triggered when the boiler detects insufficient boiler pressure for proper use. It is important to know why your boiler pressure has dropped, as in some cases, a professional boiler repair is recommended.

Below are some causes of dropped water pressure and whether they can be handled by a homeowner or require a Gas Safe Registered engineer.

Loss of Pressure in a Sealed Heating System

Sealed central heating systems can experience some pressure loss over time. This happens due to temperature changes, the release of microscopic air pockets, and the expansion and contraction of water. This process is slow and usually takes several months.

When this happens, homeowners will notice the pressure gauge slowly dropping the needle until the boiler eventually displays the E119 error code and shuts off.

Solution

You can repressurise the boiler using the filling loop, and it’s a normal maintenance task. The key thing here is that your temperature should stay stable otherwise, you should contact a Gas Safe Engineer.

Recently Bled Radiators Without Repressurising

Bleeding radiators releases trapped air, which improves the heating efficiency of your boiler. However, it also allows water to escape from the system. If your boiler is not topped up after bleeding the radiators, system pressure can drop significantly, triggering the E119 boiler fault code.

These problems normally happen:

- During seasonal radiator bleeding

- After cold spots are visible on radiators

- When performing routine DIY maintenance

Solution

Repressuring the system and bleeding radiators are safe tasks which homeowners can do. Make sure to always refill the system to the manufacturer-specified pressure once you’re done bleeding.

Leaking Radiators, Valves or Pipework

Leaks are a common cause of an E119 error code. A very slow leak can significantly reduce system pressure over time. These can occur in your radiator valves, pipe joints, and hidden pipework behind walls or under floors. To spot a leak, look for damp patches, hissing sounds, and rust marks.

Solution

Any repair work should be carried out by a Gas Safe Registered Engineer, which includes pipework and boiler connections. However, homeowners should visually inspect and find any leaks themselves.

Fault in the Pressure Relief Valve

The pressure relief valve is an important safety component that releases water when the system pressure exceeds a preset limit. If the valve is worn, stuck open, or blocked, it can discharge water continuously even when the boiler pressure is normal.

Solution

The Pressure Relief Valve is a safety component and must be serviced or replaced by a Gas Safe Engineer.

Expansion Vessel Problem

The Expansion Vessel is responsible for absorbing pressure changes when the water in your boiler heats up or cools down. If the expansion vessel’s internal diaphragm fails or loses air, the system cannot accurately regulate pressure. An expansion vessel problem can cause:

- Pressure to rise excessively high during heating

- Pressure drops rapidly when cooling

- Frequent PRV (Pressure Relief Valve) discharge

- Repeated E119 boiler codes

Recently Installed Heating Components

If you’ve just installed or replaced any part in your heating system, trapped air can escape from the system for days or even weeks. Once the air is released, pressure drops can trigger the E119 boiler fault code.

This happens mostly when:

- Installing a new radiator

- Replacing a boiler part

- Major system maintenance

Solution

Repressing is safe for homeowners. But if the pressure continues to fail, this can indicate a leak or installation issue, and a certified engineer should be contacted.

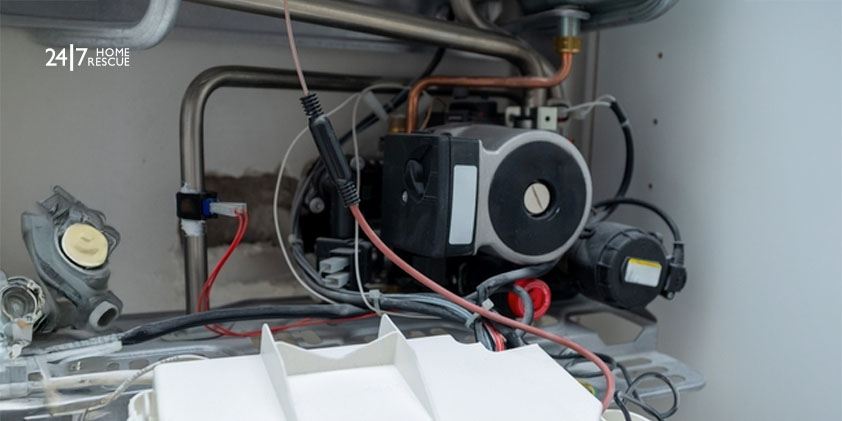

Internal Components Failure

In many cases, pressure loss can be due to internal boiler faults. These can include damaged seals, faulty pressure sensors, or leaks in internal pipework. These faults are difficult to diagnose and require specialised equipment.

If all external causes are fixed and the boiler is still dropping pressure, internal components might be causing the E119 boiler error code.

Solution

Internal boiler components should be looked after and repaired by professional Gas Safe engineers.

Boiler Repair

Book your boiler repair service online and save time and effort. Our certified engineer will provide you with hassle-free assistance.

Importance of Understanding Boiler Error Codes

Having in-depth knowledge about your boiler’s error codes is important for boiler maintenance. It allows homeowners to stay calm during unexpected breakdowns and technicians to perform accurate diagnoses and solve the issue. A fault code can highlight the main reason of a boiler malfunction so that engineers can target specific boiler components which are linked to the root cause.

Conclusion

The Baxi E119 error code is a safety warning indicating low system pressure, and it can be resolved by repressurising the boiler. You can now better determine why an E119 error is displayed on your boiler. Additionally, regular pressure checks during an annual boiler service can better detect significant pressure loss before an E119 error code appears.

Boiler Service

Ensure your boiler runs efficiently and safely with our professional boiler servicing. Regular maintenance will save you money in the long run and potentially prevent breakdowns.

At 24|7 Home Rescue, we aim to keep our blogs accurate and helpful at the time of publication. However, details such as images, services, or product information may change. Content is for general information only and not professional advice. For the latest updates, please review our Terms & Conditions or contact us directly. 24|7 Home Rescue accepts no liability for actions based on outdated or incomplete content. Our team is always happy to help with any questions.