Important Function of Combi Boiler Pipes Explained

Looking to install a combi boiler? It is important to understand one’s pipework. A combi boiler provides both central heating and hot water from a single unit. This eliminates the need for an individual water tank, making it an ideal choice for UK homeowners looking to save space.

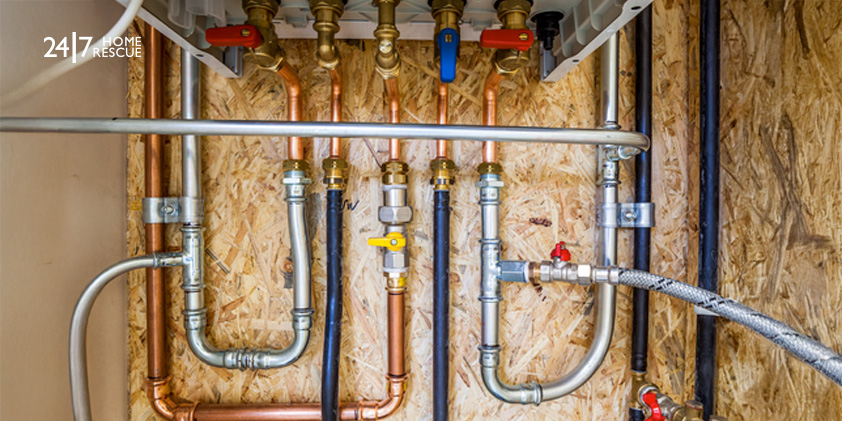

The pipework of a combi boiler includes a flow pipe that carries hot water from the boiler to the radiators and taps, and to the return pipe. The return pipe brings back cool water for reheating.

Other pipes include the gas pipe, mains water pipe, condensate pipe and boiler flue. Each of these pipes plays a vital role in your combi boiler’s operation.

Homeowners can better understand how their heating systems work by knowing the key components of the pipework. Keep in mind that timely servicing is important to the efficiency of your combi boiler.

Essential Takeaways

- Flow and return pipes are vital for moving water through the boiler system.

- Combi Boilers provide both heating and hot water from a single unit.

- There can be some problems within the pipework of a combi boiler.

- A combi boiler pipework installation must be compliant with the relevant regulations.

Understanding a Combi Boiler

A combi boiler is a single unit that facilitates both central heating and hot water for homes. Boilers typically require a hot-water cylinder or a cold-water tank, which can take up significant space. Combi boilers are known to be efficient because they condense water vapour from the exhaust gases, which minimises energy costs.

If you already have a combi boiler, a boiler cover can help prevent unexpected breakdowns. It protects you from costly repairs or replacements if your boiler breaks down. This includes the engineer’s fees, labour, and the price of parts being replaced.

Working of a Combi Boiler

Firstly, the boiler heats water through the mains pipe when you turn on the hot water tap. The flow and return pipes carry hot water to the radiators, and the return pipe returns the cold water for reheating.

The gas supply pipe supplies the gas required for heating, and the condensate pipe drains the condensate formed during the process.

The pressure relief valve ensures the system maintains a consistent, safe pressure level. Lastly, the flue pipe is responsible for releasing exhaust gases from your home.

Combi Boiler Pipework Explained

Let’s examine the Combi Boiler Pipe connections in detail so you can make an informed decision when investing in one.

Boiler Gas Pipe

The gas supply pipe is important for the proper operation of your combi boiler. It provides a conduit for natural gas or LPG to reach your boiler’s burner.

The key factor for the gas pipe is its proper size, which ensures sufficient fuel for combustion. Inaccurate sizing can lead to performance issues and safety risks.

The material used to form this pipe is copper or stainless steel. Regular checks are important for preventing leaks, which can create dangerous situations.

Mains Water Pipe

The main water pipe provides cold water from the mains directly to the boiler. The water is heated and used for the central heating system and domestic hot water. The main water pipe is essential to the central heating layout of your combi boiler.

It maintains a consistent water pressure, which, when reduced, can prevent the boiler from functioning properly.

Condensate Pipe

This pipe is responsible for removing acidic water produced during combustion. Installing this pipe accurately is key to preventing blockage or freezing, which may cause the boiler to shut down.

Additionally, this pipe must be properly installed and positioned to ensure efficient removal of acidic water.

Boiler Flue

The boiler flue carries exhaust gases from your home, produced during combustion. Ensure the removal of exhaust gases such as carbon monoxide from your home through a professional installation of your combi boiler.

Moreover, the flue length and material must comply with the relevant regulations for a safe and efficient operation of your combi boiler.

Function of Flow and Return Pipes

Flow and return pipes transfer hot water between the radiators and the boiler. The return pipe brings back the cooled water for reheating, and the flow pipe carries hot water from the boiler to the radiators.

It is important to install the flow and return pipes with the correct combi boiler pipework sizes to ensure consistent heating in your home. Keep in mind that issues like blockages and airlocks can occur in these pipes and should be resolved promptly.

Central Heating System

Keep your home warm and energy-efficient with our one-off central heating system servicing. Extend the life of your system, reduce energy bills, and avoid unexpected issues.

Pressure Relief Valve: Protecting Against Boiler Overpressure

The pressure relief valve is responsible for keeping a consistent pressure level in your boiler system. This valve releases excessive pressure to prevent damage to the boiler or an explosion.

It is important to perform regular maintenance checks on the Pressure Relief Valve to ensure it functions correctly and protects homeowners and the boiler from catastrophic failure.

Common Problems with Combi Boiler Pipes

In a combi boiler, all pipes must be free of defects as they play a vital role in delivering hot water and heating efficiently. Issues with your combi boiler’s pipes can lead to inefficient performance, and the boiler may also display error codes. The following are the common problems with your combi boiler pipes:

Frozen Condensate Pipe

This is a common issue that can occur with your condensate pipe during the winter season. A common cause of this problem is the pipe’s external position without sufficient insulation. You can try thawing the pipe and insulating it. If you’re unsure, try contacting a Gas Safe engineer to resolve the frozen condensate pipe issue.

Low Mains Water Pressure

Combi boilers rely a lot on mains water pressure. If the main water pipe has low water pressure, you might notice reduced hot-water flow and inconsistent temperatures in your showers and taps.

Leaking Flow and Return Pipes

Leaks in your flow and return pipes can reduce the system pressure and even cause boiler lockouts. These leaks are mostly caused by worn joints, corrosion, and improper installation. You should contact a Gas Safe Register engineer to solve any such issue.

Blocked or Improperly Installed Condensate Pipe

As we discussed above, a frozen condensate pipe can freeze. Another issue is improper installation or incorrect size. This can cause fault codes to show up and prevent the boiler from operating normally until the issue is resolved. Try contacting a certified boiler engineer to resolve this issue.

Airlocks

Air trapped in the flow and return pipes can disrupt water circulation, causing your radiators to go cold. You can resolve this issue by bleeding your radiators or by performing a system power flush.

Gas Supply Pipe Issues

The gas supply pipe can be blocked, undersized or otherwise affected, resulting in pressure drops. The boiler will not ignite or maintain a consistent flame if this issue persists. This is why gas pipe problems should be resolved promptly by a Gas Safe Register engineer.

Inadequately Insulated External Pipes

This indicates that the condensate pipe, or any external pipework, is poorly insulated and is exposed to freezing and heat dissipation. Get your pipes properly insulated to improve efficiency and minimise unexpected heating system breakdowns.

Combi Boiler Pipework Installation Regulations UK

The installation of combi boiler pipes and the combi boiler in general in the UK is regulated by several governing bodies to ensure safety and compliance. The following are the key governing bodies:

- Gas Safe Register: For Gas Safety

- UK Government: For building regulations

- HHIC (Heating and Hot Water Industry Council): For condensate pipework

The following are the key points to consider for a combi boiler installation:

- A Gas Safe Registered Engineer should carry out all the installation work of a Combi Boiler.

- The pipework should be accurately sized to ensure proper gas flow to the boiler.

- Flue must be carefully positioned to windows, doors and ventilation openings. Must comply with Building Regulations Part J.

- Condensing pipes must have a properly installed condensate discharge pipe.

- There should be ample room for ventilation and servicing.

- New boilers must meet the minimum efficiency standards under Part L.

Note that after the installation process has concluded, the engineer must contact Building Control, and you should receive a Building Regulations Compliance Certificate confirming that your installation meets legal standards.

Additionally, the following are the parts of the Building Regulations your boiler installation must comply with:

- Part J: Combustion appliances and fuel storage

- Part L: Energy efficiency, including minimum boiler efficiency standards

- Part G: Hot water safety

- Part P: Electrical safety for any electrical work involved

- Part H: For drainage (related to condensate pipework)

Getting Your Boiler Serviced on Time

As you can see, there are many essential components, including pipework, that are critical to keeping your heating system running without issues. A timely boiler service is vital to your heating system’s reliable operation and helps keep your combi boiler’s pipework in good condition.

A boiler service includes a Gas Safe Register Engineer performing some routine checks and assessments on your boiler. These include checking the boiler for signs of damage, evaluating the gas pressure, and confirming that safety measures are working correctly.

These regular boiler checks are required to identify any issues before they lead to an unexpected breakdown.

Boiler Service

Ensure your boiler runs efficiently and safely with our professional boiler servicing. Regular maintenance will save you money in the long run and potentially prevent breakdowns.

At 24|7 Home Rescue, we aim to keep our blogs accurate and helpful at the time of publication. However, details such as images, services, or product information may change. Content is for general information only and not professional advice. For the latest updates, please review our Terms & Conditions or contact us directly. 24|7 Home Rescue accepts no liability for actions based on outdated or incomplete content. Our team is always happy to help with any questions.